Pc numerical Manage (CNC) processes happen to be the foundation stone for modern industries, developing parts within an automated vogue at unimaginable production speeds. CNC precision machining has taken it even even more, incorporating accuracy and simplifying the manufacturing procedure.

When compared with injection molding, CNC machines provide a speedier level of speed. In distinction to injection molding, which often can get months to make a mould and guarantee the machined parts are inside of tolerance, CNC machining can produce objects in months.

Effectively, for most of these goods also to the issue of how they are produced, the answer is identical – CNC precision machining.

It's typical for designs to start as hand-drawn sketches to grasp The fundamental concepts on the component. The pc-Aided Style and design (CAD) designer then refers to those sketches to generate the graphical model with accuracy in dimensions.

A graphical product is necessary to build any part. This can be achieved with the help of Laptop-Aided Design (CAD) software program. The CAD application allows the designer to produce 2nd and 3D styles of any element for manufacturing.

Automobile producers ought to layout prototypes of those CNC machined parts right before production as innovations are additional to their recent car or truck revisions.

Precision can also be essential for beauty or normally obvious parts, where the absence or deformities or imperfections wouldn't be appropriate. Some items may possibly demand typical machining for interior parts and precision machining for outward-going through or surface parts, in which noticeable blemishes would diminish the visual high-quality from the product or service or lead to basic safety issues (with accidentally sharp edges, by way of example).

As an example, wood legs to get a eating table is often developed with a straightforward CNC lathe, and metal cutting can be done with electrical discharge machining. Here are several with the furnishings applications of the CNC machine:

Form milling Procedure really helps to machine curves and straight lines in just one Slice. Fashioned cutters can use for vertical and horizontal milling machines and might ground towards the contour of the workpiece. The contour is usually ground with an individual-stage fly cutter.

A significant issue to note is usually that for almost any software, CNC technology supplies its Rewards provided that excellent CNC companies are used. 3ERP is a leading CNC machining products and services provider, ready to satisfy any manufacturing requirements and custom orders as demanded.

Yu has traveled to Russia regularly in the last 10 years on business enterprise, his social websites posts demonstrate. 1 graphic from a excursion to Moscow in 2012 shows Yu and Bredikhin, in addition to a previous co-owner of Bredikhin’s organization.

A graphical product is important to assemble any component. This can be done with the usage of Pc-Aided Design (CAD) software package. The CAD plan permits the designer to develop 2nd and 3D styles of any section for manufacture.

The applications of CNC machining while in the aerospace more info industry are vast and reputable. A lot of the machinable aerospace factors include engine mounts, fuel flow factors, landing gear components, and gas accessibility panels.

Other customers have incorporated the producers on the Ka-52 attack helicopter and also the maker in the Buk missile system, Based on government procurement records.

Mr. T Then & Now!

Mr. T Then & Now! Tatyana Ali Then & Now!

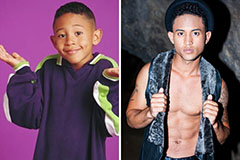

Tatyana Ali Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Elin Nordegren Then & Now!

Elin Nordegren Then & Now! Tyra Banks Then & Now!

Tyra Banks Then & Now!